Shopping Cart

0 item(s) - POA- About us

-

Products

- - Air Filters

- - Alloy Connectors

- - Back Plate

- - Bearing Housing

- - Blow Off Valves

- - Boost Controllers

- - Cam Pulleys

- - Cast Manifolds

- - Compressor Wheels

- - Fans

- - Fuel Lines & Fittings

- - Fuel Pressure Regulators

- - Fuel Pumps

- - Fuel Surge Tanks

- - Heat Shield

- - Heat Wrap

- - HEAVY DUTY T-BOLT CLAMPS

- - Intake Manifolds

- - Intercoolers

- - Oil Catch Tanks

- - Oil Coolers

- - Performance Turbochargers

- - Radiators

- - Silicone Hoses

- - Stainless Steel Straps

- - Standard Turbochargers

- - Throttle Bodies

- - Turbine Housings

- - Turbine Wheels

- - Turbo Blankets

- - Turbo Cores (CHRA)

- - Turbo Repair Kits

- - Turbo Timers

- - Waste Gates

- Delivery

- Information

- Payment Options

- Contact us

- Whatsapp - 062 457 8450

How turbo's work

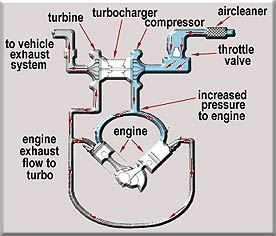

Turbo charging forces compressed air into an engine to improve a vehicle’s performance. With turbochargers, a smaller, more fuel efficient engine can replace a larger, less fuel efficient engine. The smaller engine achieves similar performance, while reducing exhaust emissions.

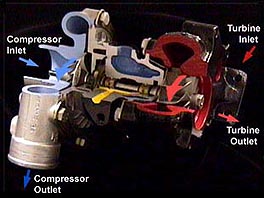

The turbocharger is driven by waste exhaust gases forced through an exhaust housing onto a turbine wheel. The turbine wheel is connected by a common shaft to a compressor wheel so that both wheels rotate simultaneously when the exhaust gases hit the turbine wheel. Rotation of the turbo assembly compresses the intake air routed through a compressor housing, forcing the compressed air into the engine’s cylinders. The increased amount of air forced into the engine creates more power than a similarly sized non-turbocharged engine and power similar to a larger, non-turbocharged engine. Turbochargers operate at very high temperatures, high speeds and high pressures. Optimum performance can only be achieved by the proper operation, maintenance and service.

Service Tips:

Change your engine oil at the recommended intervals.

Service your turbo at the recommended intervals.

Use only qualified and experienced specialists to service your turbo.

Check out any oil leaks, excessive or unusual noise and vibration as soon as they occur.

Lack of power, excessive noise, black or blue colored smoke are more likely to indicate engine problems than turbo problems.

Wait for the engine oil to reach normal operating temperature before revving the engine excessively.

Let the engine idle for a couple of minutes before switching the vehicle off.